Build Robust Automotive Batteries with Infineon’s BMS Chipsets

One of the major challenges in developing automotive BMS is maintaining the lifetime accuracy and robustness without blowing up the cost of the bill of material.

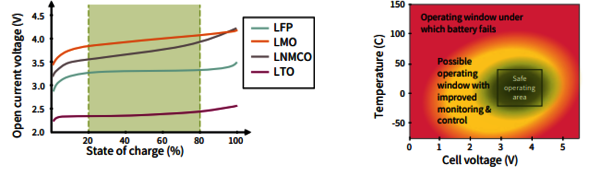

All electric vehicles are driven by lithium-ion (Li-ion) batteries. Despite the drastic cost drop in the Li-ion battery cells, the battery remains the most expensive part in an electric vehicle. As such, maximizing the battery performance and lifetime is a key objective for Mild-Hybrid, Plug-in-Hybrid, Full-Hybrid and Battery-Electric Vehicles (xEV) to be sustainable. Such an objective is challenged by the complexities associated with Li-ion battery cells. To mention few, Li-ion chemistries are known for their extremely flat State of Charge (SoC) curve and sensitivity to environmental (e.g. temperature) and aging elements (e.g. number of charging cycles). Additionally, operating the Li-ion cell outside its safe operating area can drastically reduce its lifespan and even damage it. Thus risking the safety of the passengers.

To overcome the challenges mentioned above, a Battery Management Sytem (BMS) is required

The primary Functions of the BMS are:

- Monitoring of the battery cells’ conditions (e.g.: voltage, temperature, current, pressure, etc.)

- Calculation of all the battery states (e.g.: states of charge (SoC), health (SoH), power (SoP), safety (SoS), etc.)

- Protection of the battery by disconnecting it during critical events (e.g. over current event) or request the thermal managements intervention (e.g. cooling or heating the battery when needed)

- Optimization the performance of the battery (e.g. by feeding the charger with the optimal charging protocol to extend cell life)

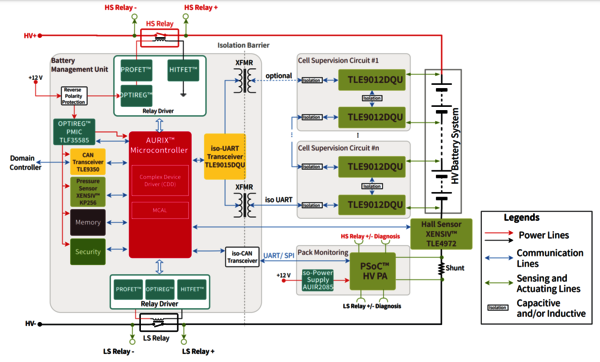

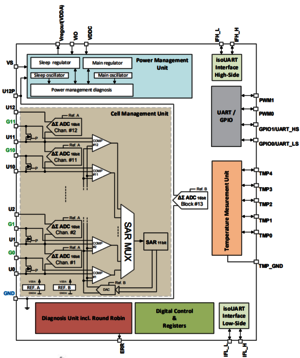

Sense and Balance Cells Accurately with TLE9012DQU

Cell Monitoring and Balancing (CMB) is directly attached to the cells. Its key function is to monitor the cells’ temperature and voltage. The greatest challenges of the CMB lay in the following points:

- A CMB is attached to an “always on” system. Even when the battery cells are empty, they maintain more than 50% of their nominal voltage. Thus, a CMB is more prone to aging than most of other components in the car.

- A CMB is directly connected to a high voltage system. Thus isolating the CMB and protecting it from hotplug events is necessary.

- The CMB needs to maintain highest level of functional safety (ASIL-D). Any error in the measured voltages or temperature could result in missing on dangerous events such as thermal runaway.

To address these challenges, Infineon developed TLE9012DQU

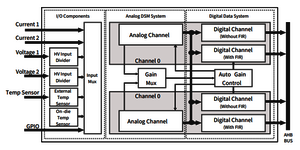

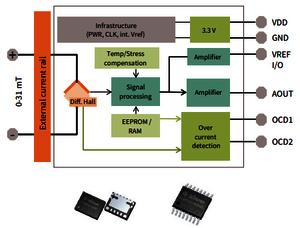

Measure the Current Accurately and Fast with PSoC™ HV PA Shunt IC and TLE4972 Coreless Hall Sensor

The pack monitoring unit sits in the junction box and is responsible for monitoring the packs current values, isolation and disconnection. The current measurement is needed for:

- Accurately calculating the state of charge with Coulomb counting. Every error in state of charge is a loss in battery capacity which means loss in car mileage.

- Over Current Detection (OCD) due to e.g. short circuits or isolation failure. The earlier an over current is prevented, the less the automobile manufacturer (OEM) needs to upsize the wirings of the DC bus.

To accurately calculate the state of charge and fast over current detection an accurate current sensor is required. Infineon has developed PSoC™ HV PA, and TLE4972 to address these challenges.

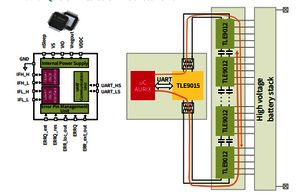

Communicate with CMBs Robustly and Safely Redundant with TLE9015DQU iso UART Transceiver

All CMB measurements and actions need to be communicated to and from the main BMS controller. However, the different CMB units sit in different voltage islands. This means that isolated communication is required, to transmit information safely between the CMB and the main BMS controller. The challenge however when building the isolated communication lay in the following points:

- Robustness of the isolation: The battery pack operates under very electrically noisy conditions, so the stability and quality of the transmitted information can be drastically impacted by the isolation.

- Bandwidth and latency: Operating and measuring all CMBs synchronously is impacted by the bandwidth and latencies of the communication solution.

- Power consumption: Booting the system via the communication links, with no power consumption.

- Safety: Meeting the appropriate ASIL level and a fail operational state of the communication. Otherwise, if the communication with the AFEs breaks, the entire pack will need to be disconnected.

- Cost of isolation: There are many ways to isolate the communication, but the cost of isolating can become very expensive.

To address these challenges, Infineon developed TLE9015DQU

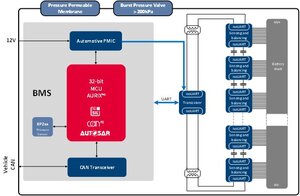

Build High Performance Battery Control Unit (BCU) with AURIX™ MCUs

Li-ion battery is represented using complex mathematical models. Such models give a deeper insight into the state of the battery cells as well as the individual components surrounding them. Additionally, such models might be adapted over time, if the OEM discovers an improved version of the model. As such, a BCU is responsible for running all the battery algorithms, housekeeping and communicating with the domain controller. Such a BCU will mainly consist of a powerful microcontroller supporting ASIL-D qualification. For that purpose, Infineon developed AURIX™.

The new 40 nm µC generation TC3xx AURIX™ from Infineon Technologies ideally fulfills all requirements for the required processor of the BMS

Achieve ASIL-D Safety Level BCU Easily with OPTIREG™ PMIC Family Products

The high voltage battery is a highly important component when it comes to safety. Any undetected errors by the BMS might lead to serious failure of the entire vehicle. Thus risking the safety of the passengers. As such, BCUs must be designed to meet ASIL-D safety level requirements. In addition to the AURIX™ features, the OPTIREG™ PMIC family enable easy realization of ASIL-D in the BCU.

For that, Infineon developed TLF35584QVVS1 and TLF35584QVVS2

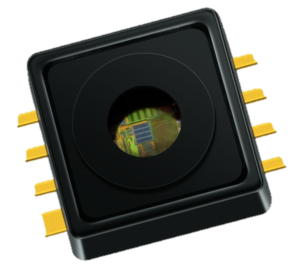

Detect Early Thermal Runaway with KP23x and KP25x Pressure Sensors

Thermal runaway is by far the worst thing that could happen to a Li-ion battery. It not only leads to the total damaging of the battery but also possesses a life-threatening hazard upon the passengers. As such an early and accurate thermal runaway detection is crucial.

Besides a cell temperature monitoring via the TLE9012DQU sensor inputs, Infineon developed a set of pressure sensors KP23x and KP25x which can be used to additionally monitor the pressure in the battery. This can ensures a more accurate and early thermal runaway detection.

System ASIL-D Safety Level

Development Boards

AURIX™ 2G TC397 Application Kit

With Infineon’s radar-specific evaluation board fitted with an AURIX™ TC397XA TFT, customers can connect through a dedicated Radar Interface MMIC and quickly start developing, evaluating and testing a full radar application.

The board features various communication interfaces such as CAN FD, Gigabit Ethernet, SPI FlexRay as well as an LCD XGA Display. It also gives access to all the digital and analog IOs available from the LFGBA-292 package of the microcontroller.

Get in Contact with our Experts